Sony Image Sensors: The Revolution in Industrial Automation with Precision and AI

Sony’s image sensors are synonymous with innovation in industrial automation. Combining high performance, artificial intelligence, and easy integration, these components are transforming the industry.

Why invest in Sony image sensors for industrial automation?

Sony has been recognised for its excellence in image sensors for decades. choosing their image sensors means betting on proven innovation. That’s why their applications in industrial automation ensure exceptional results, offering high resolution with fast and reliable readings.

Additionally, they are compact and easy to integrate with existing systems. Thus, by investing in Sony’s image sensors, you reduce adaptation time and almost immediately increase productivity.

Moreover, these image sensors are recognized for their versatility, as they adapt to many applications, from visual inspections to smart robotic systems. Therefore, using Sony’s image sensors for industrial automation strongly benefits your company in terms of quality control and performance.

Enhancing Industrial Automation with Sony's Image Sensors

Sony’s image sensors are designed to meet the demands of the modern industry.

They use advanced technologies that eliminate distortion in images of fast-moving objects, ensuring precision even in high-speed environments. Logically, this feature is essential for the reliability of inspections and measurements on automated production lines.

Additionally, Sony’s image sensors are used in machine vision systems, which are also applied in industrial automation. This integration enables the development of customized solutions for inspection, control, and identification, increasing efficiency and reducing human errors in production processes.

Applications of Sony Image Sensors in Industry

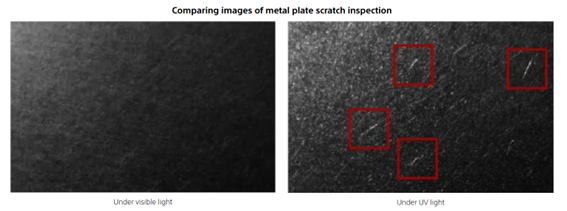

Sony’s image sensors shine in applications that require high precision. For example, in the metal industry, the IMX487 model detects scratches on plates using ultraviolet light.

This high-definition IMX487 image sensor provides high sensitivity and low noise, improving inspection accuracy. Therefore, almost invisible defects are eliminated right on the production line.

Similarly, sensors like the IMX264 are ideal for high-resolution inspections. With 5MP and low noise, they are widely used in computer vision systems. In this sense, they ensure that no error escapes quality control.

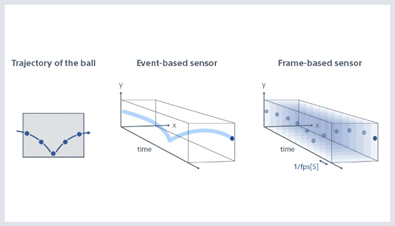

Another example is the IMX636, which is based on event-based vision (EVS) that detects fast movements. Among event-based vision sensors, the IMX636 has the smallest pixel size in the industry, at 4.86 μm.

Unlike a conventional frame-based image sensor, it captures only differential data. This means that the trajectory of a moving element is captured with very high temporal resolution.

Therefore, the IMX636 is perfect for detecting fast-moving objects, equipment monitoring, motion detection analysis, and accurate image recognition. Furthermore, its energy consumption is extremely low.

Examples of Sony’s Image Sensors to help you achieve better productivity

Sony offers a wide range of image sensors, each with specific features to meet the diverse needs of the industry. Here are some components for you to explore.

SONY IMX250

This Sony CMOS image sensor is considered to be in the smallest pixel size class in the industry for industrial applications. This feature allows for high-resolution images using a smaller lens than other existing products. Certainly, this sensor is ideal for accurately identifying fast-moving objects without distortion of the focal plane.

SONY IMX487

This UV image sensor allows for the detection of scratches and imperfections on metal surfaces, essential for quality control. Due to its portability and high resolution, it is suitable for industrial automation but also for outdoor use, such as infrastructure inspections.

SONY IMX556

SONY IMX556 is a high-resolution indirect time-of-flight (iToF) image sensor.

As a compact and innovative image sensor, it is highly accurate for applications such as forklift pallets detection, load recognition, fruit picking equipment, and automatic milking robots.

SONY IMX264

Sony’s polarization image sensors solve the problem of conventional CMOS image sensors, which cannot identify fast-moving objects. They provide analog memory within each pixel, allowing for high image quality without distortion of the focal plane. Their increased processing speed is ideally used for various industrial applications, such as quality control.

SONY IMX636

Finally, this is the Sony event-based vision (EVS) sensor, which outputs high-speed and low-latency data, emitting only differential data after combining with coordinate and time information. Due to these features, it can be applied in recognition processing systems to increase data delivery efficiency. In other words, it is ideal for detecting fast-moving objects, equipment monitoring, motion detection analysis, and image recognition.

Are you looking to increase your productivity with Sony’s image sensors? Contact Macnica!

Each of Sony’s image sensors guarantees efficiency, speed, quality, and precision. And they all come with precise documentation and specialized technical support from Macnica.

Therefore, integrating these technologies into your system is easier than it seems. And Macnica can assist you at every step, from selection to implementation. Contact us and discover how Sony’s technology can revolutionize your industrial process.