STREAL for Robotics and AMRs

Give your Robots and AMRs True Force Awareness

Embedded force and strain sensing for safer collaboration, higher precision, and fewer unplanned stops

Robots, grippers, and AMRs experience critical forces inside their mechanisms, including inside fingers, links, joints, fixtures, and frames. Traditional sensors such as wrist-mounted force-torque sensors, load cells, and motor current detection only measure forces at the periphery, far from where slip, overload, chatter, fatigue, or micro deflection occur.

This leads to:

- Missed local events such as slip, minor collisions, bending and overload

- Unwanted stops and unstable grip thresholds

- Reduced pick accuracy and poor insertion repeatability

- Undetected structural fatigue and alignment drift

Engineering teams need local, high-resolution sensing inside the mechanism, not only at the wrist or in a separate transducer.

STREAL for Robotics and AMRs

STREAL is a semiconductor-grade microstrain sensing platform that installs inside joints, grippers, toolholders, spindle housings, and AMR frames. Each module measures strain along a primary axis, with resolution down to 0.1 µε, and converts it to digital force, load, or torque signatures for your controls or quality teams.

Instead of relying on one peripheral sensor, STREAL enables local and distributed sensing with multiple compact nodes placed directly on structural members. You get local signals that improve precision and uptime without major redesign. This complements existing tools you already use.

If your application needs certified absolute load or a 6-axis force vector at the wrist, keep those tools in place and add STREAL where space and localization matter.

The result:

- Higher precision for gripping, insertion, and approach motions

- Higher uptime through early detection of overloads, binding, or fatigue

- Better contact awareness without major mechanical redesign

Why Robotics Teams Choose STREAL

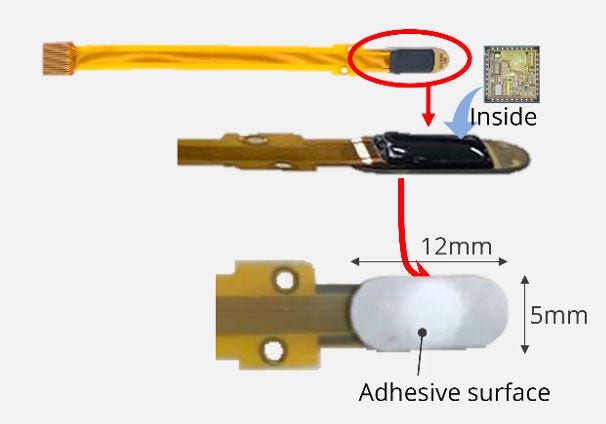

- Ultra-compact sensor modules (2.5–3.2 mm² silicon die) with integrated ADC, amplification, temperature compensation, and diagnostics

- Proven placements on industrial robots, cobots, grippers, AMRs, and rotating assemblies

- Macnica sensor-to-solution support for placement design, calibration workflow, firmware, dashboards, and pilot-to-production scaling

STREAL Products: SR300 and SR500

SR300

Optimized for low-power IoT

Best for: battery nodes, wireless retrofit, AMRs

- Resolution: 1 µε

- Signal bandwidth: 1.3 kHz

- Typical power: ≤ 3 mW

- Die size: 2.5 mm × 2.5 mm

SR500

Optimized for high-precision industrial use

Best for: industrial robots, spindles

- Resolution: 0.1 µε measured at 1.3 kHz

- Signal bandwidth: up to 20 kHz

- Typical power: about 70 mW

- Die size: 3.2 mm × 3.2 mm

- Integrated functions: on-chip ADC and amplifier, temperature compensation, and self-diagnostics

Where STREAL Goes on Robots and AMRs

End Effectors and Grippers

What they do

Mount STREAL directly to the finger body, jaw, or toolholder to measure:

- Microstrain from gripping forces

- Slip events and mis-grips

- Overload and shock events during pick-and-place

- Deformation signatures correlated to part geometry or hardness

Outcomes

- Tighter grip windows based on real strain thresholds (not inferred current limits)

- Real-time slip detection without bulky tactile arrays

- Higher pick reliability in small-part or high-mix environments

- Reduced nuisance stops for collaborative robots

What you install

- One STREAL module bonded to the gripper link or finger

- Quick mechanical prep, single-axis calibration routine

- Connect force signatures to your PLC or dashboard

- Macnica assists with threshold derivation and data QA

Joints and Links

What they do

Place STREAL on link plates, gearbox housings, or joint structures to capture:

- Contact and collision forces invisible to wrist F/T sensors

- Backdrive or binding forces in reducers and bearings

- Bending/torsional strain that impacts positional accuracy

- Early fatigue indicators in robot arms

Outcomes

- Improved repeatability through monitoring of link deflection

- Safer human-robot interaction with local collision detection

- Early detection of abnormal loads before failures or downtime

- Higher stiffness validation for precision applications

What you install

- 2-4 sensors distributed across load paths for vector reconstruction

- Short calibration routine

- Threshold logic configured by the customer

- Macnica provides placement simulation guidance and data handling help

Spindle Housings and Fixtures (Machine Tools / EOAT Machining)

What they do

Embed STREAL at the spindle housing, toolholder, or fixture face to monitor:

- Cutting-force signatures

- Tool wear progression

- Chatter onset

- Fixture deflection due to clamping/load variation

Outcomes

- Reduced scrap through earlier detection of cutting anomalies

- Optimized tool life and predictable tool-change intervals

- Immediate root-cause visibility when quality trends drift

- Mechanical load contextualization that vibration sensors often miss

What you install

- One module bonded to the spindle or fixture housing

- Calibration against known tool or load conditions

- Continuous signature monitoring with thresholds and trend windows

AMR Frames and Mounts

What they do

Bond STREAL to steel members and frame nodes of AMRs to detect:

- Overload conditions from shifting payloads

- Fixture loosening, stress risers, and early crack propagation

- Impact events and route-dependent force patterns

- Long-term fatigue under mixed-duty cycles

Outcomes

- Higher fleet uptime through early fault detection

- Improved ride stability under dynamic loads

- Event-to-route correlation for operations analysis

- Predictive frame-health monitoring without retrofitting bulky sensors

What you install

- 2-3 modules on frame or mount locations

- Simple software thresholds and fatigue trending

- Macnica assists with review of data signatures and alert integration

How to Start Fast with an Evaluation Kit

What’s included:

- Evaluation unit with reference firmware, sample scripts, and onboard configuration tools

- Quick-start guidance for bonding, orientation, calibration, and data streaming

- Example dashboards and event traces for threshold setting

- Customer controls all alert thresholds; schematics not provided

Your 2-4 week pilot:

- Select 2-4 sensing points on a robot or AMR where force signatures matter

- Install and run a simple calibration cycle (5-10 minutes)

- Collect and review real events under live duty cycles

- Set thresholds, validate actions, and tune alert workflow

Macnica reviews your data and recommends next steps for scaling.

Frequently Asked Questions

Do I need to replace my wrist force-torque sensor or load cells?

No. If you need a certified load or full 6-axis vector, keep them. STREAL adds local, embedded sensing where space and localization matter.

Who sets the alert thresholds?

You do. Macnica supports with data interpretation and process integration.

Which materials work best?

Bond to monolithic metal structures (steel links, frames, fixtures). Avoid highly compliant or laminated surfaces.

How small is the hardware?

Each STREAL module uses a tiny semiconductor strain sensing system with integrated ADC, amplifier, and temperature sensor. Typical flex modules are under 66 mm.

Next Steps

Request an evaluation kit today or contact us for a quote or more technical information.

Talk with Macnica Americas about placement design, calibration workflow, and data integration.